Electrifying Fluid Power: Advancing Smarter and More Sustainable Machines

Power & Motion

By Paolo Patroncini

Oct. 23, 2024

The pairing of electric and hydraulic technologies will be necessary to meet the efficiency and performance requirements of electric machines.

The rise of electrification is rapidly displacing diesel’s dominance as industries move towards cleaner and more efficient power solutions. Yet, transitioning from diesel engines to electric systems is far more complicated than it seems, especially when hydraulics are involved.

Fluid power provides manufacturers with an inefficient but necessary solution that remains irreplaceable for heavy-duty tasks — like in construction, mining, and agriculture. The importance of hydraulics comes from delivering the best available performance and trade-offs between additional power requirements and complex size, weight, and configuration constraints despite the inefficiencies.

So, rather than abandoning hydraulics, the future requires electric solutions that modernize fluid power and enhance its efficiency through electrification.

Market Trends Driving the Shift Towards Electrification

Although electrification is advancing, diesel is still the main power source for hydraulic machinery. However, this is changing as electric solutions become more prevalent.

For example, from 2023-2030, the construction equipment market is expected to grow by 3.8% annually, while electrified equipment is projected to experience rapid growth of 23.6% annually during the same period.

Several factors continue driving this rapid shift, including government incentives, consumer demands, and cost reductions. Experts expect that these market forces reshaping industries worldwide will only gain more momentum.

1. Government incentives

Many countries have ambitious targets for reducing carbon emissions; electrification is crucial to achieving these goals. Governments use incentives like tax breaks, subsidies, and grants to encourage investment in electric and hybrid technologies. For example, California’s Clean Off-Road Equipment Voucher Incentive Project (CORE) helps companies switch to electric non-road machinery.

2. Customer demands

Today’s consumers increasingly prioritize clean, quiet, and efficient machinery. Moreover, growing environmental awareness coupled with the practical benefits of electric machinery — such as reduced maintenance and easier regulatory compliance — fuels this demand.

In the European Union, for example, diesel vehicle registrations plummeted from 36% in 2018 to just 16.4% by 2022, reflecting the region’s strict emissions regulations and push for greener alternatives. The U.S. demonstrates similar rising trends in electric vehicle sales.

3. Cost reductions

Hydraulics will remain an important part of many electric machines, like the Volvo compact excavator pictured here, necessitating proper integration of electric and fluid power technologies to achieve desired performance requirements.

Although electric machinery often has a higher upfront cost, the total cost of ownership (TCO) over a machine’s lifespan stays significantly lower. As battery and charging technologies improve and economies of scale take hold, experts expect these initial costs to drop further.

Pros and Cons of Hydraulic Systems Compared to Electrified Alternatives

For decades, hydraulic systems made up the backbone of industries that demand high power and precision. Even as electrification accelerates, this fluid power technology remains essential in numerous applications due to its many advantages.

For example, hydraulic systems are:

- Significantly lighter than their electrified counterparts, especially in high-power applications like material handling. Electric systems require larger, heavier battery packs to match the performance of hydraulic systems, which can affect the overall weight and mobility of machinery.

- Capable of delivering high power output for their relatively compact components. Electric motors, while improving, still struggle to match the sheer power density of hydraulic actuators in certain heavy-duty applications like construction. This power density also proves advantageous in mobile applications where space is at a premium.

- Durable in harsh environments, capable of operating effectively even in extreme temperatures, dusty conditions, and high-vibration environments. Electrified machinery can be more sensitive to these conditions, particularly when it comes to electronic components and battery performance in extreme temperatures.

- Generally less costly upfront, making them more accessible for many industries. While electrified systems may offer lower operational costs over time, their high upfront investment can take several years to offset. This is particularly true for applications requiring high force output, where the cost of electric actuators and the necessary power electronics can be prohibitive.

Hydraulics continue to provide many advantages to heavy-duty mobile equipment including high power output, durability for use in harsh environments and familiarity for many machine owners.

For all their advantages, hydraulic systems aren’t perfect; one of their primary drawbacks lies in energy waste, particularly from pressure drops across valves. As pressurized fluid moves through these control points, significant energy is lost via friction and heat generation. This inefficiency has long been a point of criticism for hydraulic systems, especially in an era where energy conservation is paramount.

The challenge moving forward is to find ways to combine the strengths of both technologies to create more efficient, powerful, and sustainable systems.

A Methodological Approach is Needed to Pair Electric with Hydraulics

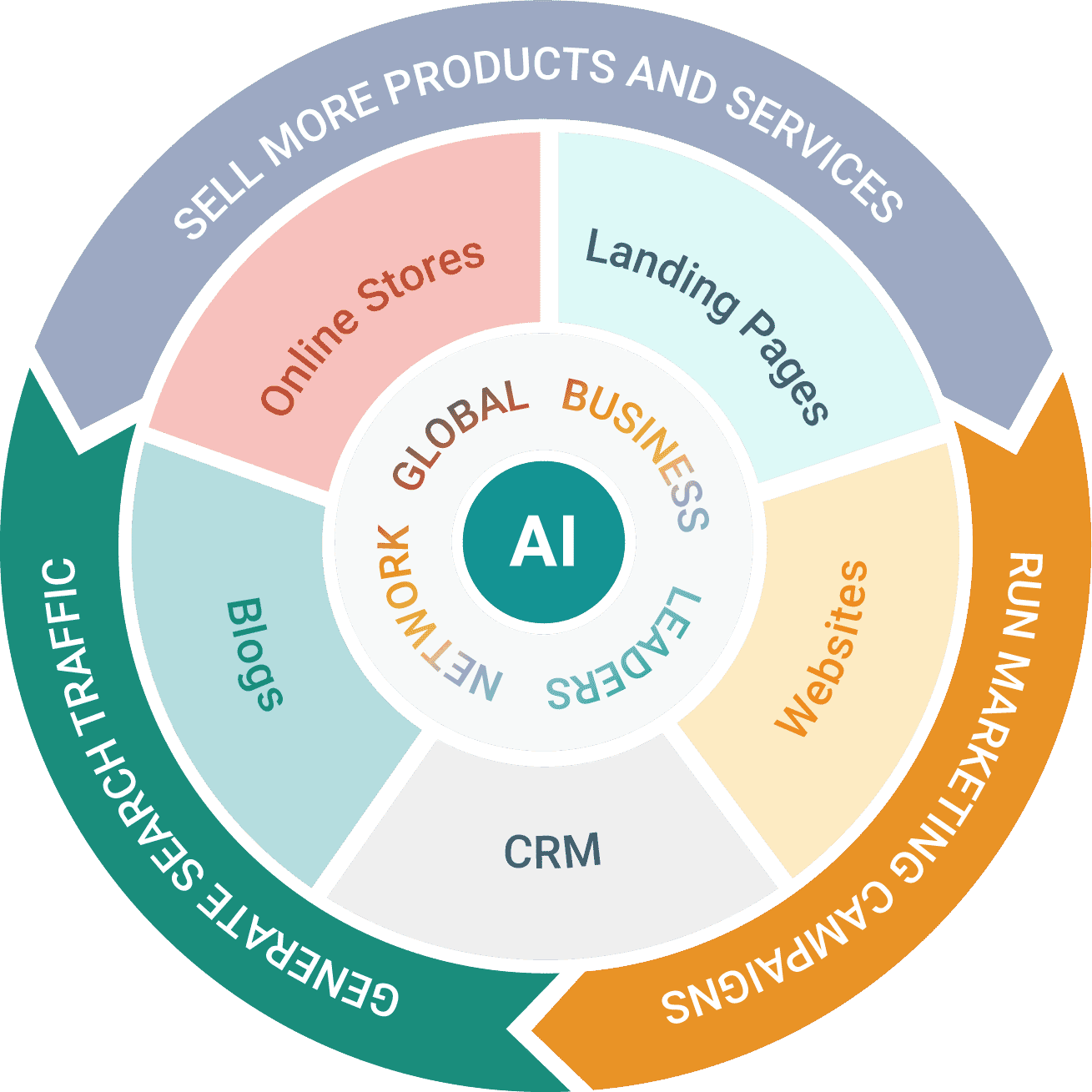

Rather than viewing hydraulics and electric systems as competing technologies, OEMs should focus on integrating their strengths to create more efficient and powerful machines. Achieving this integration requires a methodical approach centered on a comprehensive analysis of power consumption and machine operation.

Two key steps form the foundation of this approach:

- Power absorption mapping — Every machine has a unique duty cycle, and understanding these cycles is essential for optimizing system performance. By mapping how much power each machine consumes at different stages of operation, it’s possible to identify areas where energy efficiency can be improved.

- Simulation — Once the power absorption data is collected, simulations can be used to predict how the new system architecture will perform with a battery pack. This enables designers to predict performance under real-world conditions, optimizing operational time and energy consumption. Simulation also allows for improved packaging, ensuring the new system fits within the machine’s existing design with minimal changes.

By leveraging these steps, OEMs can fine-tune both power usage and component placement. This ensures that electric-hydraulic systems meet performance goals efficiently and within the machine’s existing size, weight, and configuration requirements.

Hydraulic System Improvements

Electrification alone doesn’t always improve system efficiency. Transitioning to electric drivetrains requires rethinking hydraulic systems in non-road machinery. To truly benefit from electrification, fluid power systems need significant modernization for electric integration.

Key areas requiring redesign include:

- Vehicle controls — Electrification demands more advanced control systems to ensure that hydraulic components and electric motors work seamlessly together. Traditional hydraulic controls may not provide the precision or responsiveness needed in an electrified system, particularly for material handling and lift access applications.

- Cooling systems — Hydraulic systems generate considerable heat. That’s fine for liquid power systems since they are natural coolants, but electric components can be sensitive to high temperatures. Integrating electric power requires a revamped approach to cooling, ensuring both hydraulic and electric systems operate within optimal temperature ranges.

- Fluid distribution networks — As noted previously, how hydraulic fluid is moved and managed within the system greatly impacts overall efficiency. Modernizing these networks to work with electric systems and minimize loss or capture otherwise wasted energy is critical to improving system performance.

Integrating hydraulic and electric technologies requires a methodical approach which takes into consideration power consumption and machine operation.

Therefore, manufacturers must develop innovative solutions to ensure hydraulic systems can be successfully and safely paired with electric power — a challenge leading OEMs are actively addressing today. Without this modernization, any potential gains from electrification could quickly be offset by the inefficiencies of hydraulic components.

Integrated systems which bring together electric and hydraulic technologies can help ensure more optimized electric vehicle performance.

Development of Electric-Hydraulic Systems

Once the new architecture is designed and the components that need to work together are identified, the next step is to develop the system in conjunction with electric motors and driver technologies.

This has two aspects: developing the control software and validating new features via testing.

Control Software Development

Modern electric-hydraulic systems can collect and process more data than traditional systems, leading to a new generation of control capabilities. This software needs to:

- Integrate seamlessly with both the electric and hydraulic components.

- Optimize power usage based on real-time operational data.

- Implement advanced features like predictive maintenance and adaptive control.

This software highlights one of the greatest strengths of a modernized electric-hybrid solution. Unlike diesel-powered options, electrification enables advanced integrations to optimize every vehicle’s use and lifecycle touchpoint.

Testing and Validation

Before implementing these new features in actual machines, it’s important to use a dynamometer for testing, which allows for:

- Isolated testing of the electric-hydraulic system.

- Verification of system performance under controlled conditions.

- Refinement of control algorithms without the variables introduced by a full machine.

The software development and testing should be done in a controlled environment, separate from the machine. This isolation helps avoid any disturbances or variables the machine might introduce, ensuring accurate and reliable testing results.

Testing of electric-hydraulic systems ensures they will perform as desired in electric vehicle applications.

Powering a Sustainable Tomorrow with Electric-Hydraulic Machinery

Electrifying fluid power systems is a promising path forward, challenging as it might be. With many drivers paving the way — from government incentives and customer demand to advancing technology and reduced cost — it’s only a matter of time before adoption accelerates even faster.

In many ways, hydraulic machinery faces the same dilemma (although on a smaller scale) as diesel engines. Despite its inefficiency, electric alternatives lack the raw power necessary for specific jobs in their current state.

The future of fluid power is likely one where electric and hydraulic technologies coexist and complement each other. By leveraging each power’s strengths, OEMs can deliver more efficient, powerful, and environmentally friendly machines.

Source: https://www.powermotiontech.com/hydraulics/article/55235414/zapi-group-electrifying-fluid-power-advancing-smarter-and-more-sustainable-machines