The Role of Robotics in Revitalizing American Manufacturing

TEDx Talks

By Saman Farid

5 Nov 2024

Saman Farid: So, how many of you by a show of hands remember during COVID going to a grocery store and seeing shelves like this? Well, it’s not fun, right? Uh, I think a lot of the things that we relied on a daily basis were unavailable. Um, it was very difficult to just get by, uh, doing the most basic things. You know, these are consumer products, things that we use on a daily basis.

But if you go, you know, the parts of the power plants needed, we’re missing the parts that airplanes needed, we’re missing the parts that, uh, you know, we use to run our cell phones and to build things, all of them are missing. Uh, and it was an incredibly difficult time for all of human civilization. Uh, recently, uh, if anybody was following the news, there was a dock worker’s strike.

And again, you know, there was this massive shock to the supply chain. Luckily it didn’t last very long. Uh, but it was just a reminder to us of how dependent we are on this flow of goods and on the ability to build all the most basic things. Um, and this is all a reminder for us that the global manufacturing base, this giant machine that feeds us all of our daily needs, uh, is incredibly, incredibly, uh, fragile at any moment, you know, things could go wrong and we would be really, really suffering.

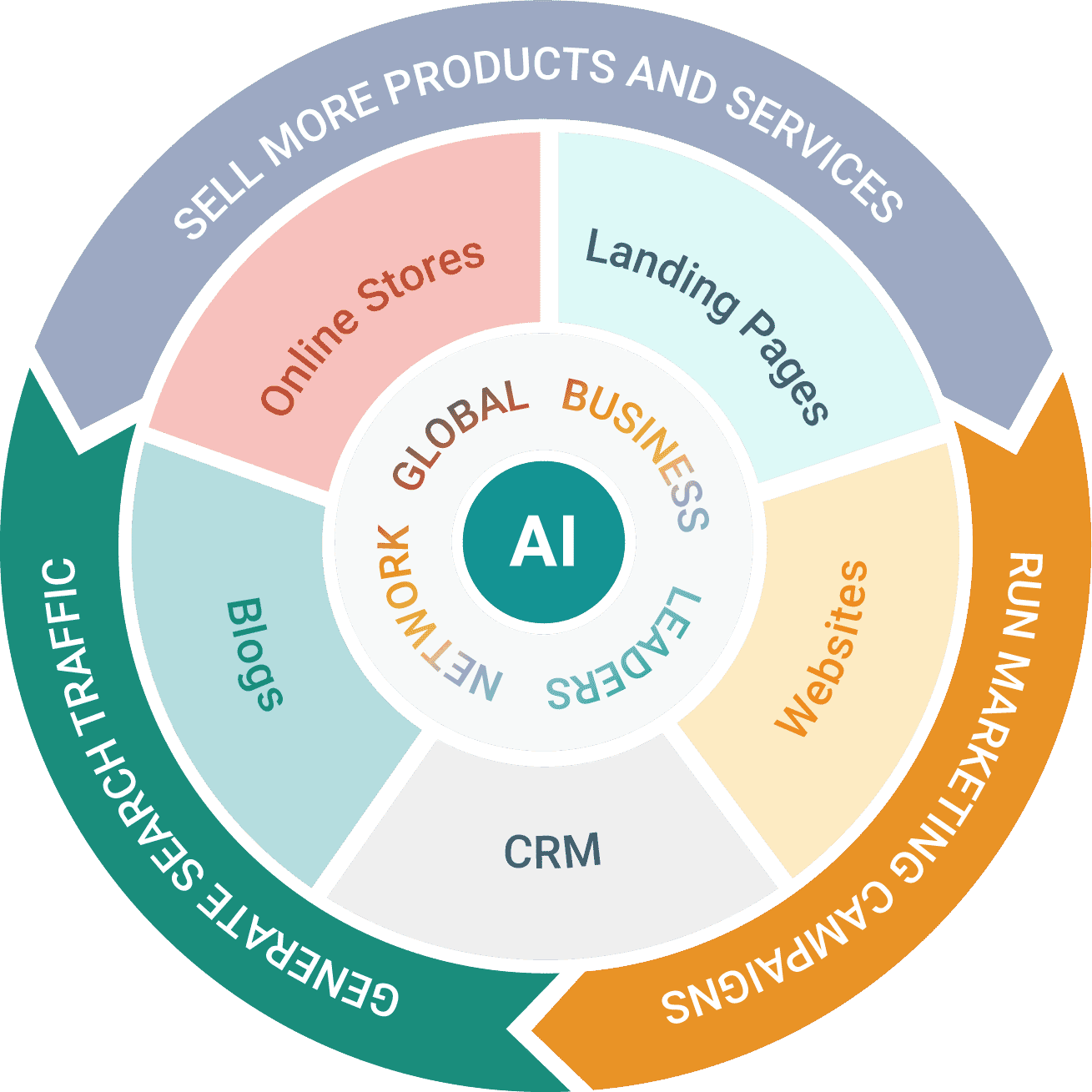

Um, and, and, uh, I’m here to tell you a little bit about how AI, how robotics is going to change that landscape. What are the things that are happening right now? What are the things that we can do about it?

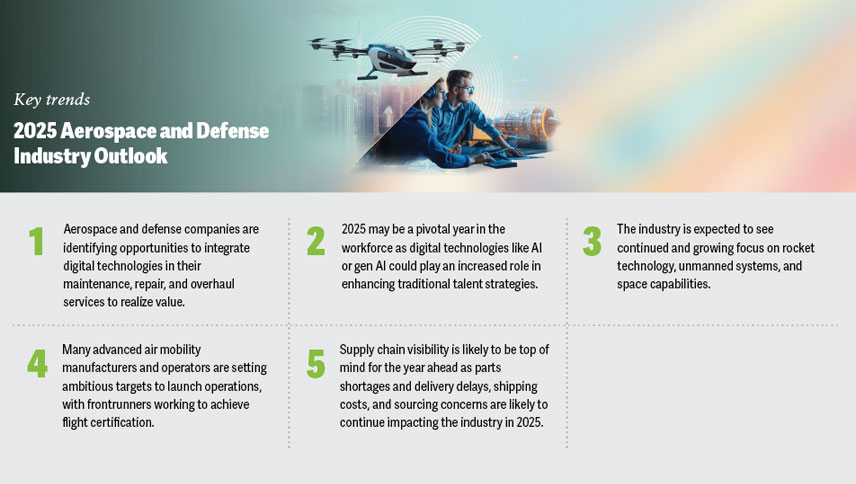

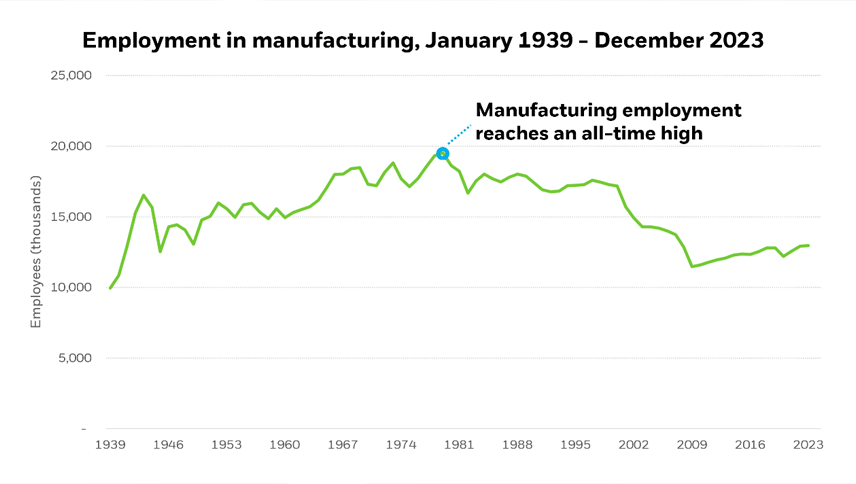

Um, so first fact to know, uh, is today in America, American manufacturing is really, really suffering. And this is not just an American phenomenon. This is global. There’s a massive demographic demographic problem that’s leading factories to be extremely, extremely uncompetitive more and more of them are shutting down every single day in America, about half the factories have shut down since about 30 years ago and the ones that do remain are sitting idle 65 percent of the time.

So every factory out there, you know, they build giant facilities and forklifts and they have air conditioning and have trucks and they have all this stuff. Uh, and all of it ends up sitting idle two thirds of the production hours, uh, in, in, in, uh, in the day. Uh, and a lot of this is a result, a result of, uh, this, you know, really vicious, uh, cycle in the manufacturing process, which is, uh, where we are today.

If you look at the stat here on the bottom, there’s one and a half million unfilled manufacturing jobs today in America. Uh, if you expand that globally, it’s even more. And if those factories that are sitting idle 60 percent of the time, we’re actually operating at full capacity, there’s another 5 million people that we need just to run the factories that we have right now.

Um, and so, you know, these factories are, are, are, are incredibly desperate to have more people to help them build these products. Because they’re so desperate and so shorthanded, the people that are working there actually have to pull, you know, multiple double duty. They have to do a lot of very dangerous tasks that are complex and painful.

Uh, they’re unhappy, and so worker turnover is very high. The typical factory in America has about 200 percent per year headcount turnover. That means for every job, they have to replace that, that position twice, uh, a year on average. There’s many jobs more than that. Um, and so the end result of all of this, you know, challenge, uh, in the manufacturing process is that they end up making worse products at much higher prices.

Uh, and this is really one of the core reasons for inflation. Um, where all the products that we need and use on a daily basis Just become worse and they become, uh, more expensive. Uh, and naturally the next result of that is that there’s less demand for those products. And that leads to this vicious cycle where the factories are even less productive than they were before.

Uh, and this cycle just gets worse and worse. Uh, so this is something that we really have to figure out ways to break out of today. Uh, so i’ll talk to you a little bit about kind of where I come from and my background and why i’m so passionate about this topic. Um, you know, so I, I may not look like it, but I grew up in China and I lived in China during a time when of massive industrialization, uh, from when I was six years old until I was, uh, about twenty five, I lived there.

And I got to see, uh, you know, when I, when I, I remember when I moved to China, for those of, those of you who speak Mandarin, one of the most common things you would hear when you go to a store and ask for something is they would say, mao, which means, sorry, we don’t have it. Uh, and, uh, you know, this was, you know, just coming out of communism.

Uh, and so, uh, you know, China had really not built a strong supply chain. And, and, and in the, in the 20 plus years that ensued, uh, we saw massive industrialization, we saw the, the, uh, capability to build all kinds of products. And that led to this, uh, advancement and, and moving up, uh, 400, 500 million people out of poverty.

Um, and, and so seeing that was really something that, that stuck with me. I myself, you know, love, love to tinker. I’m a builder. I love to figure out how things work. That led me to go and, uh, go to New York. I studied engineering, uh, and I learned how to actually build things with my hands. Uh, I worked on that.

I built a couple of companies and then I worked in venture capital, which is this kind of place where you get to luckily live a little bit in the future. Uh, being here in Silicon Valley, I think many of you get to experience that as well. And we see all these incredible technologies on a daily basis coming out of academia, coming out of large companies, people build all this stuff that looks futuristic.

And as an, as a venture capitalist, I invested in. Companies that used, you know, robots to pick apples and robots that would sort garbage and robots that would do all these incredible tasks for us. Uh, and in my mind, I was like, this is a foregone conclusion. You know, these things are going to be everywhere, uh, any day now.

Uh, and seeing all that technology was, was incredibly inspiring. Uh, the reality is I was very disappointed when, when many of those companies didn’t actually make it to scale. Um, and then COVID hit, which was this, you know, massive shock to the system. It was a reminder to me, and I think many of us. That all of these products that we rely on on a daily basis, uh, were very hard to come by.

And if we didn’t drastically adopt more robots, you know, we would be, be stuck. And so I started Formic. We’ve now deployed in about a hundred something, uh, factories across the U S and I’ve seen and heard from a lot of them about why it is that robots are so hard to get into use in the real world. Uh, so as I think I’ve already made clear, you know, manufacturing is not really this kind of standalone thing that just happened somewhere else.

And we get to buy products. It actually is upstream from all the things that we do. Whether it’s, you know, the medicines that we, that we use to stay alive, whether it’s the military, whether it’s agriculture and food, whether it’s cars and airplanes, you know, everything relies on having a strong and powerful manufacturing base.

Uh, and so, uh, you know, despite that, uh, right for every single product, even these kind of very complex and advanced products like jets and solar panels and, uh, you know, electric cars, uh, you know, we, we continue to invest in what’s seen as the, you know, the sexy parts of manufacturing all of these cool and incredible complex products, but actually what under what underlies that is we have all of these very foundational.

Components that are needed to build those products. You can’t build a solar panel without brackets and, you know, aluminum extrusions, you can’t build a jet, uh, you know, without kind of turbine blades, you can’t build a car, uh, without rubber wheels, uh, and all of these things are the accumulation, uh, of what leads to us being able to build these products for an interesting stat here is for, uh, for any single automotive plant, uh, that you hear about.

There’s about 3, 000 suppliers that build all of the subcomponents that feed into that, uh, feed into that automotive plant. And on the other side, you know, robots are, are available, right? Like as I was talking about as an investor, I was investing in robotics. Robots actually seem to do a lot very, very well already.

Uh, they’re very capable. Uh, there’s a lot of tasks that they can already do very reliably. But, uh, something that maybe many people may not know is that robot adoption is, is abysmal right now. Uh, in America, about 90 percent of factories don’t have a single robot, uh, anywhere to be seen on the floor. Uh, and this was a, a stat that, that is I think very, very shocking for most people.

Um, and it’s really only in this kind of the green triangle that you remember from my earlier slide, these kind of very advanced plants, you know, they’re really well automated. People who make chips and people who make, uh, cars, uh, are two examples, but all of their suppliers, uh, are not. Um, and. And the real reason for this is that for most manufacturing facilities, adopting robotics and automation is kind of out of this world complicated.

I was in a factory a couple of weeks ago where This is a plant that used to make parts for the Ford Model T. Uh, it was started, uh, you know, in the early 1900s by the great grandfather of the person who’s running it now. It’s a family owned business. It’s been passed down one generation after another.

It’s still run by the same guys. And, uh, if you go and look around in the plant, it looks like it’s still in the 1900s. You know, all the equipment is still from then. Uh, and if you’re, you know, spent all of your time thinking about how to build this specific metal part, Or if you spend all of your time making chocolate chip cookies, uh, or you spend all of your time making, uh, you know, dog food, which are all, are all factories that we put robots into and you ask them, uh, about their journey with robotics.

What they say is the same every single time. They say three things. Number one, I know I’m going to go out of business if I don’t get robots. Um, number two is I’ve been trying to get robots for the last 10 years. Uh, I’ve been trying to figure out ways to automate. Uh, and number three is I still don’t have any robots.

Uh, and so it’s really, really challenging and difficult for these manufacturing facilities to automate. And one of the reasons is that, you know, this, what you see here at the bottom, uh, for every 11 factories in America, there’s only one, uh, you know, robot programmer available. Uh, and honestly, you know, to, to automate a plant, you need, you know, probably 50 or 100, uh, robot programmers to be able to, uh, to get these jobs done.

Um, but you know, the good news is, you know, we’re at a very important moment in a turning point in this, in this story where AI is making robots much more intelligent, much more capable, uh, but also all the subcomponents that you need in order to make a robot work, you need to evaluate the site and you need to do 3D scanning, you need to generate code, you need to figure out all the parts, you need to be able to reconfigure that robot, all of those are becoming faster and easier, uh, by the day.

Um, and so, you know, this is, I think, an example where, uh, this is a phrase you hear a lot in Silicon Valley, where the future is here, uh, but it’s not evenly distributed yet. For technology to really get into the hands of the people who need it the most, there’s a huge divide that needs to be crossed, and there’s this bridge.

Uh, and so, you know, I started thinking about, you know, where, where has this bridge been, been, been crossed before? And there’s a lot of industries where this has happened. Uh, and I think this is something for those of us here in Silicon Valley who think about technology on a regular basis. Uh, you know, just inventing the technology is really not nearly enough.

Uh, we really have to figure out how it gets adoption in the real world. Um, so in the case of, of email is, is one of my favorite examples. You know, for those who may remember, there was a time where if you wanted to have an email address, Your only option was to, you know, have a giant air conditioned room in your office and have a bunch of, you know, large server racks and have a bunch of people who manage the IT of it and pay hundreds of thousands of dollars of software licensing fees before you could actually have an email address.

And as a result, most people just didn’t do it. For the vast majority of people, we just didn’t have email. And it wasn’t until this kind of generation of operators came around that said, we’re going to create hosted services for you, we’re going to manage it on your behalf, and you’re going to be able to access it.

access these technologies, um, that we saw massive adoption. And the same thing has happened in industry after industry, uh, from solar panel adoption to aircraft adoption. And if you look at the history of technology, uh, there’s always this gap where, you know, something’s invented and it takes a long time for people to figure out how to actually use it at scale.

Uh, and then you see a massive adoption. And so I think robots are, are at that turning point. Uh, we’re starting to see, uh, government and private enterprise come in and start to take on the role of centrally managing the operations of robotics and helping manufacturers to automate. We work with, uh, you know, a lot of state governments, and we see that, uh, you know, there are massive programs in place to help, uh, with the adoption of this incredibly, uh, critical technology.

Uh, and why is this, you know, important to all of us who are sitting here? You know, the hope is that this really leads us to a path forward. Where we have a world of abundance, uh, we want to be able to have, you know, all of the things that we need on a, need to rely on on a daily basis available to, uh, you know, our, our children and our grandchildren.

Uh, and, uh, in order to do that, we really need to remove a lot of the stigmas around adopting technology. We need to create pathways, uh, for those who need this technology to be able to figure out how to. Thank you.

Source: https://youtu.be/EAFNnjQqvno